Designing With Intention: The R&D Journey Behind our Egg Traps

Entocycle’s R&D project to create the optimal BSF Egg Trap.

At first glance, the egg traps in Entocycle’s waste-to-insect facilities may appear deceptively simple. In reality, they’re the outcome of a nine-month long, product research and development project that focused on optimising egg collection whilst adhering to the natural behaviour of the Black Soldier Fly (BSF).

The project encompassed material research, iterative design, manufacturing and extensive A/B testing. The objective: to develop an egg trap aligned with BSF biology, whilst significantly improving the efficiency, consistency and yield of egg collection.

Why are Egg Traps Important?

BSF eggs are the lifeblood of the factory - if there’s no eggs, there’s no production. It’s crucial that they’re being collected in the most optimised way possible.

With high fertility rates of up to 1000 eggs per fly, BSF eggs are incredibly delicate and require gentle handling.

The contraptions used to collect them are called ‘egg traps’, and they have to be well designed to maximise yield, protect the sensitive eggs, along with balancing the CAPEX with the OPEX.

With something as intricate and small as this ultimately holding the weight of the entire factory on its shoulders, it’s easy to understand why the process to create the most optimal design required painstaking care and attention.

Engineering a product like this requires intricate knowledge of BSF behaviour, but also technical knowledge of how to develop scalable solutions. This is why Entocycle has a team of entomologists and engineers collaborating every step of the way, to develop insect solutions from the ground up, that mirror the natural biology of the flies. By working with BSF biology, the team not only ensures higher results with our products, but also ensures higher levels of insect welfare.

Concept Development

Every project the Entocycle team works on begins with a pain point. For our egg traps, it was an inefficiency in production and an over-reliance on manual intervention.

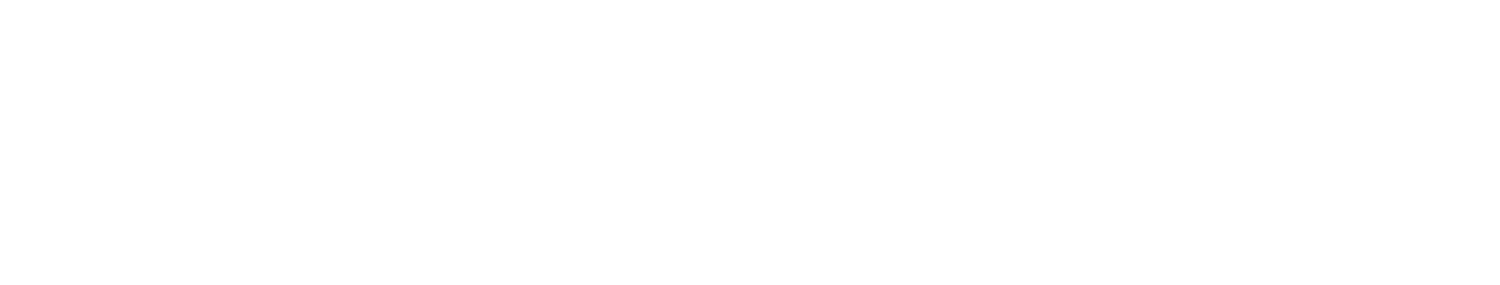

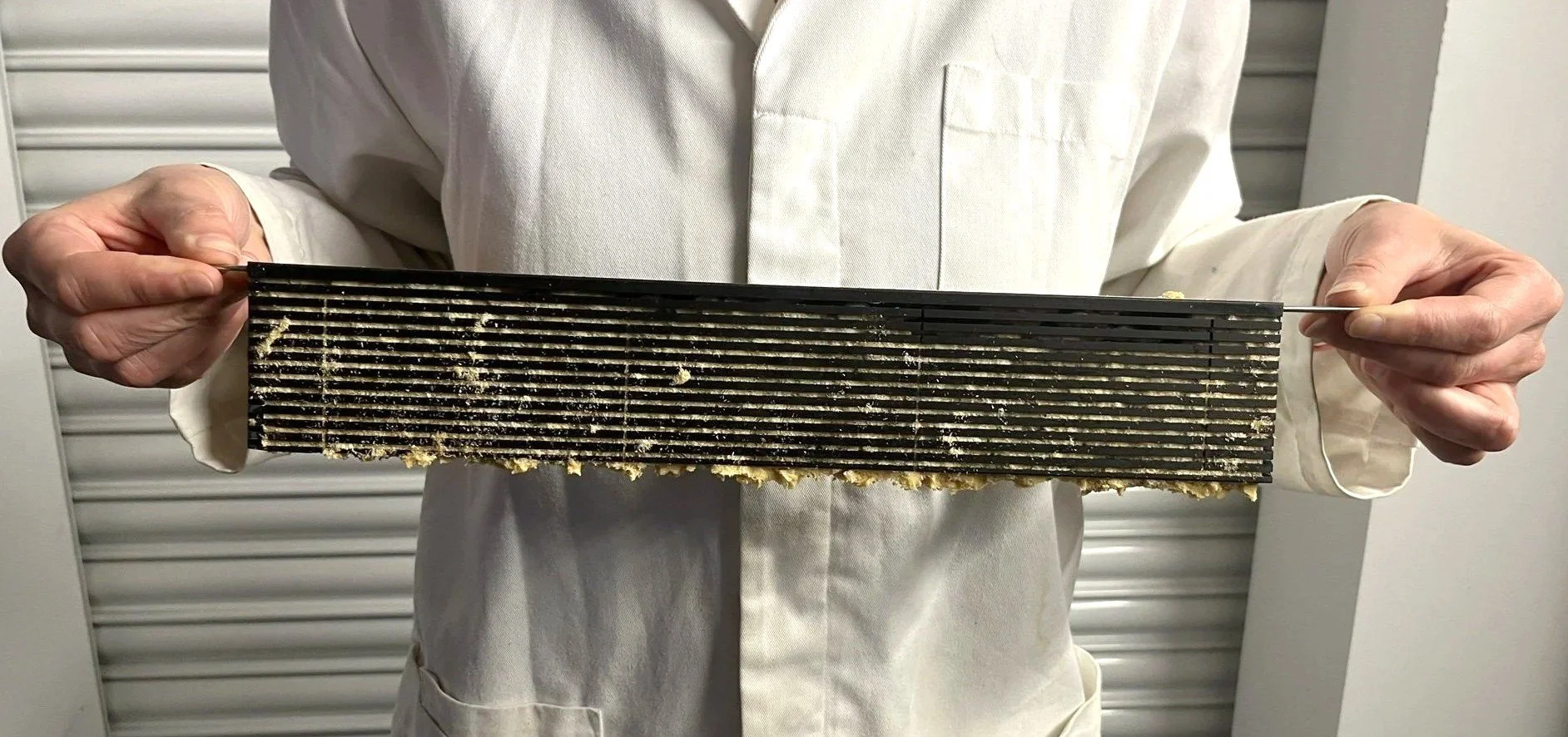

Entocycle’s original Egg Traps (pictured on the left)

The original design used wood which required frequent replacement, laborious assembly and egg scraping - which significantly increases the mortality-rate. As the fly rooms are humid, the wood absorbs water and changes shape, altering the available laying space. When looking into treatments to combat this, findings concluded that wood treatments for wet environments could’ve brought in unwanted chemicals to the fly rooms, which our entomologists clearly did not want.

Seeking a reusable, user-friendly, and simply put - better alternative, the team sent to work on the product R&D process, with the mission to create the most efficient egg trap.

Entocycle adopts a rapid-prototyping methodology, with our in-house 3D printing normally allowing our team to design parts in the day, print them overnight and test the next day. In this case, the fly biology required to test each iteration of the egg trap meant that each design had a 7-day test period. This then quickly added up, resulting in the whole process then being about 9-months long.

Naturally, there’s lots to think about when designing something as intricate and specific as BSF egg traps, but material research was where our engineers started.

Material Testing and Prototype Development

Although BSFs are traditionally attracted to natural materials such as wood, these substrates present limitations in durability, hygiene and industrial-scalability.

From the outset, it was essential that any new material supported non-invasive egg collection. As BSF neonates (newly hatched larvae) are generally 1-2mm long, extremely delicate and at risk of mortality. They’re also crucial to the functioning of the factory, so a non-invasive egg collection was non-negotiable.

Product Design Engineer, Nick, led the materials research with the three core criteria:

Manufacturability at scale.

Biological neutrality with respect to BSF behaviour.

Compatibility with non-scraping egg removal.

Another critical element was ensuring that the materials used were non-toxic and food grade, safeguarding insect health.

Entocycle’s Egg Trap material trials (pictured on the left)

After a series of material trials, polypropylene stood out as the optimal solution. It offered excellent manufacturability, durability and after multiple trials in fly cages it didn’t interfere with BSF natural behaviours, resulting in improved egg yields.

With material selection complete, the team progressed to the next stage - design optimisation.

Iterative Design and Biological Testing

The next stage involved identifying the most effective geometry and structure for egg laying and larval egress. This process involved a comparative evaluation of multiple prototypes, guided by the two primary questions:

Do BSFs actively choose to lay eggs in the structure?

Which design enables the most effective larval exit post-hatching?

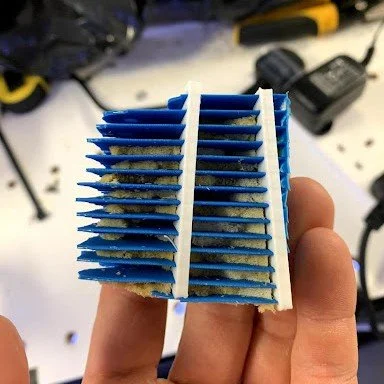

Throughout the design timeline, our engineers and entomologists developed over 20 prototypes that featured variables in shape, size, internal geometry and placement within the active fly rooms. The process followed a biology-first methodology, prioritising BSF welfare, along with maximising egg yield.

With multiple prototypes, designs were eliminated through extensive testing, including a custom silicone model with an accordion-like structure that proved impractical in use, despite its unique appeal.

Similarly, taller multi-layered designs demonstrated reduced egg deposition at higher levels, due to diminished exposure to pheromonal cues - these insights informed refinements that proved to be successful.

The testing led to 3 prototypes that incorporated varying angles. These were tested against each other to realise a final design.

Key Breakthroughs

One design featured a honeycomb outer structure (pictured above), which proved to be rather successful.

The discovery of an internal pleated design (pictured above) provided significant results, as the creation of tapered triangular gaps leverages BSFs’ preference for specific oviposition gap widths. The wider surface area allowed for a higher concentration of eggs to accumulate within a single cavity - substantially increasing capacity.

Further testing with these structures demonstrated that the eggs could be collected without scraping, which eliminated a major source of egg mortality. This discovery led to our Entomologists utilising a process called ‘Dry Hatching’, which consistently yields higher neonate survival rates compared to traditional scraping methods.

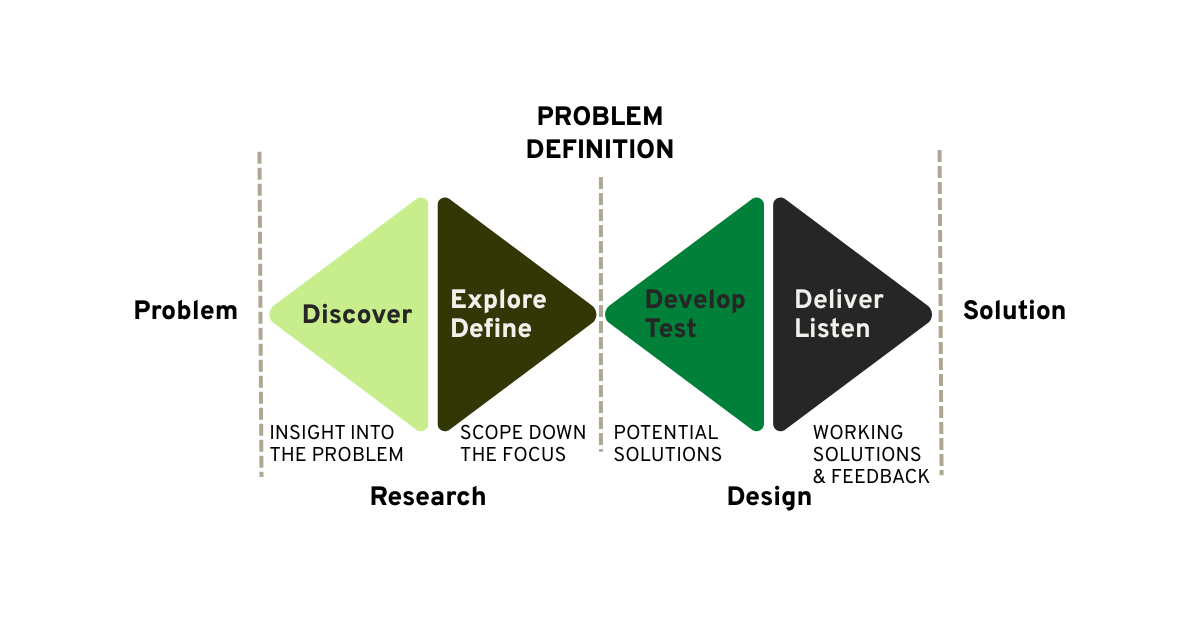

The Double Diamond Design Framework (pictured to the left)

When reflecting on the process, Nick noted the relevance of the Double Diamond Design framework, where expansive exploration is followed by focused refinement - “You start at a point then you taper outwards, so you’re researching and figuring everything out, which then leads to a point of focus, which is exactly what this process felt like.”

Entocycle’s final Egg Trap design (pictured to the left)

The final design was then implemented in-house and has since remained in continuous production since 2019. We optimise what we can measure. We’re able to tangibly see the impact of our design work on cost production through reducing labour requirements, egg mortality and increasing egg yields.

From R&D to Operational Deployment

While the final egg trap retained elements of the original product, the new improvements were substantial - extended durability, biological outcomes, operational efficiency and scalability.

Why This Matters

This is how we work - We measurably design and optimise both equipment and processes to find the most efficient solution. We’re constantly balancing the technical, the biological and the commercial, to find the sweet spot of all three that positively impacts our business model.

The R&D project for this egg trap design ultimately showcases this methodology, with the depth of our technical expertise and scientific grounding. The egg traps are one component of an entire factory system, where every single process and piece of equipment has been developed with the same rigour, backed up by 10 years of consistent R&D work.

For our customers, this provides confidence in a platform that is ahead of the curve - delivering scalable, local and sustainable alternative protein solutions. As our capabilities, team and business continue to grow, so too does our ability to shape the future of the insect farming industry.